Quasi isotropic laminates of im7 8552 carbon epoxy with a layup of 45 90 45 0 2s in the thin section were manufactured 13 to make the taper a whole block of eight plies was added at the middle of the two continuous blocks to give a thick section layup of 45 90 45 0 3s as shown in fig.

Thermally quasi isotropic laminates.

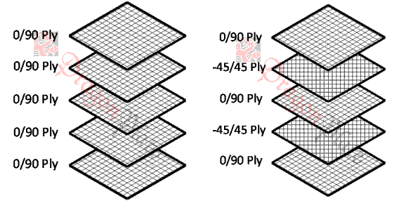

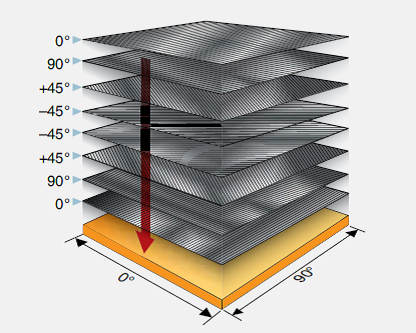

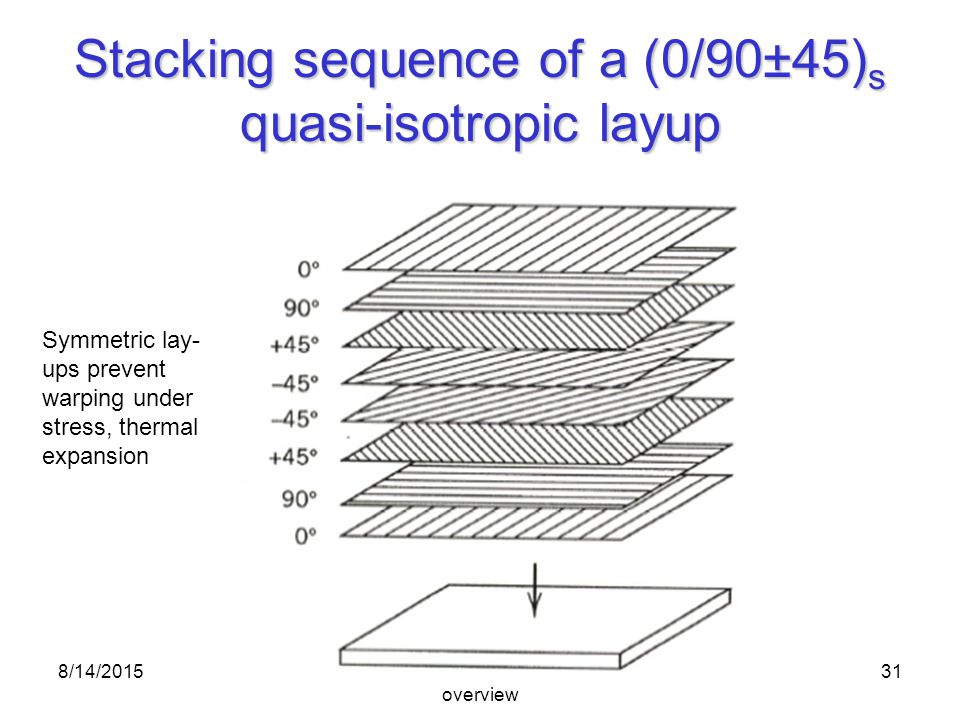

Quasi isotropic laminates are made when the orientations of the plies are balanced so that the extensional stiffness of the laminate is the same in each in plane direction.

Quasi isotropic laminates exhibit isotropic that is independent of direction inplane response but are not restricted to isotropic out of plane bending response.

For this the paper first discusses the concept of design reviews the classical laminated plate theory and the usual design rules for laminates and introduces the polar method for plane anisotropy.

Quasi isotropic laminates exhibit isotropic that is independent of direction inplane response but are not restricted to isotropic out of plane bending response.

Quasi isotropic properties can also be achieved with 0º 60º and 120º oriented unidirectional plies.

The laminate has 50 uni t300 plies and 50 uni e glass plies with each fiber layer type laid up in a quasi isotropic laminate for a total of 16 plies.

Swiftcomp tutorial that shows the computation of equivalent engineering constants and coefficients of thermal expansion of composite laminates.

This paper aims at promoting laminate designs with specific stiffness properties.

Quasi isotropic laminates have been used because they give properties like those of metals and predictable responses that are familiar although they are not optimal in strength to weight or stiffness to weight ratios many laminates used today on aircraft structures tend to be of this type.

The example provided corresponds to a quasi.

Depending upon the stacking sequence of the individual layers the laminate may exhibit coupling between inplane and out of plane response.

Typically quasi isotropic sheets are created using carbon fiber weaves with plies oriented at 0º 90º 45º and 45º with at least 12 5 of the plies in each of these.

24 9 all the plies in the dropped block were individually chamfered before curing except the 90 plies.

The determination of in plane coefficients of thermal expansion ctes of full stack composite laminates by means of thermo mechanical analysis tma.

Depending upon the stacking sequence of the individual layers the laminate may exhibit coupling between inplane and out of plane response.

The laminate is made of a combination of t300 carbon fiber eglass and rs3c resin.

The fiber volume percent of fiber compared to the resin controls the cte to a great extent.